- PRODUCT INFORMATION

- PRODUCT APPLICATION

- PACKING & DELIVERY

- OTHER

The straight seam high-frequency welded steel pipe is a kind of steel pipe made by high-frequency welding process, which has the advantages of high production efficiency, low cost and stable quality, and is widely used in various fields. The following is a detailed introduction to the straight seam high frequency welded steel pipe:

Raw material preparation: Select high-quality steel plates or steel strips as raw materials, and after cutting, calibration and other processing, ensure that the size and quality of raw materials meet production requirements.

Molding: Send the prepared raw materials into the molding unit, and process the raw materials into tubes through multiple passes of rolling and bending.

High-frequency welding: Use high-frequency current to generate heat on the welding edge of the steel pipe, so that the welding edges melt and fuse with each other to form a firm weld. High frequency welding has the advantages of fast heating speed, good weld quality and high production efficiency.

Cooling and sizing: After the welding is completed, the steel pipe is cooled to prevent the weld from overheating and causing deformation or cracking. At the same time, the diameter of the steel pipe is precisely determined by the sizing unit to ensure the dimensional accuracy and roundness of the steel pipe.

Straightening and cutting: Straightening the cooled steel pipe to eliminate bending and twisting during welding and forming. Then, the steel pipe is cut according to the customer’s requirements to form a length that meets the requirements.

Information

Finish of pipe Hot dipped galvanized with zinc 220~260g/m2;

Painted with black/varnish lacquer;

Oil on the surface to prevent rust;

Bare pipe without painting:

Epoxy painting/FBE coating/3PE coating

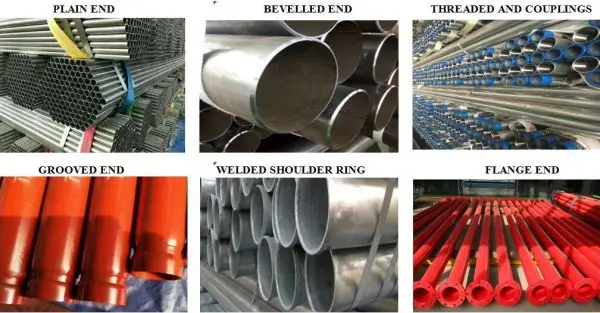

Pipe End Plain end/ Bevel end;

Threaded on two ends, one end with coupling, one end with plastic cap

Marking As per client requirement or mill standard

Products Images

PRODUCT APPLICATION

Applications Construction / building materials steel pipe

Scaffolding pipe

Fence post steel pipe

Fire protection steel pipe

Greenhouse steel pipe

Low pressure liquid, water, gas, oil, line pipe

Irrigation pipe

Handrail pipe

Packing & Delivery

Packing OD not less than 273mm: Loose packing,piece by piece.

OD less than 273mm: In hexagonal seaworthy bundles packed by steel strips.

small sizes nested into big sizes.

Techinical ERW (high-frequency welded)

Trade Term FOB, CFR, CIF, EXW, FCA

Delivery Time 15-45 days (based on quantity) after receiving advanced payment by T/T or LC .

Production Process

End Treatment

Quality Inspection

Product Application

Company Information

We are factory specializing in the manufacture and export of PV bracket System many years. We can design drawings according to your requirements. We specialize in this field for many years with high quality and competitive price.

Our main products: solar PV bracket system, galvanized steel strip, galvanized plate, galvanized sheet/coil,steel structure supporting C, Z, U,H steel beam,hot rolled strip steel, steel angle,seamless pipe,welded pipe,Gi pipe,and so on.”We specialize in this field for many years with high quality and competitive price.

If you are interested in any of our products, please feel free to contact us for more information. We are looking forward to setting up business relationships with customers from all over the world.